ATEX Certification

Since 2003, ATEX certification has raised awareness across all industrial sectors about the risks associated with potentially explosive atmospheres, including gases and dust. This directive places particular emphasis on industrial dust, which is often the cause of fire and explosion incidents. It requires a thorough assessment of dust explosion protection measures, taking into account criteria such as maximum particle size, explosion thresholds, and explosion pressure.

To identify these risks, a detailed analysis of industrial processes is required, including potential ignition sources, explosive air volumes, operating temperatures, and the probability of explosion in specific environments.

The directive classifies hazardous areas into three zones to prevent dust explosions. Zone 20, the most critical, corresponds to areas where explosive atmospheres in the form of combustible dust clouds are present continuously or for long periods, typically inside containers or closed systems.

MAC Valves and the ATEX Directive

D Coils – ATEX, UKEX and IECEx Certified

Type D coils are certified ATEX, UKEX, and IECEx, ensuring superior protection against gas and dust hazards.

Versatile and compatible with all AC and DC voltages, they optimize energy consumption with power limited to 7.3W, delivering outstanding energy efficiency. Electrical connection via armored cable or cable gland ensures robust and secure connectivity.

For tailored installations, 2-meter and 5-meter cable lengths are available, perfectly adapting to any configuration.

Pilot and Main Valve Bodies

Unmatched reliability for all your applications. Every component, from the spool to the rubber seals, is carefully manufactured in Viton® to ensure optimal performance under all operating conditions.

With lubrication specifically designed for high-temperature environments, this valve guarantees flawless operation even in thermally demanding conditions.

Featuring both internal and external pilot air options, the valve can be precisely configured to meet your specific requirements.

Its BSPP thread ensures safe and straightforward installation, enabling seamless integration into existing systems.

Supplied without a base, the valve offers maximum installation flexibility without compromising performance.

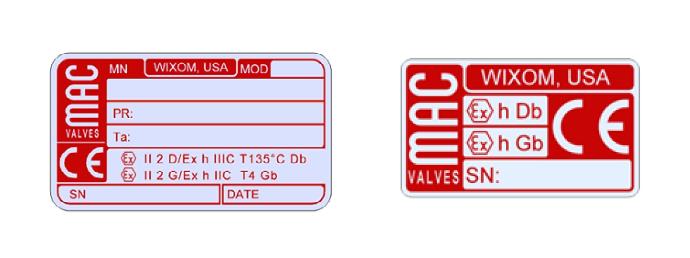

Each unit is equipped with a dedicated nameplate displaying the MAC Valves reference, unique identification number, and protection details, ensuring full traceability and strict compliance.

ATEX Marking

The main valve and pilot valve are clearly identified with the following nameplates: – The ATEX identification plate located on the side of the main body / – The ATEX identification plate located on top of the coil.

Main Valve

The plate located on the side of the main body provides the user with information about the pulse valve and its use in an ATEX environment.