MAC Valves Technology for Optical Sorting

The ultra-fast solenoid valve that gives your sorting system its precision and performance.

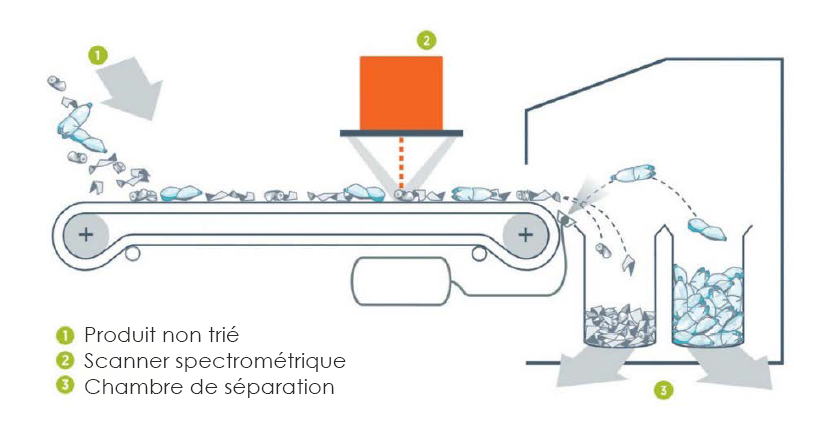

Industrial optical sorting relies on a rapid sequence between the optical detection of a product (via sensors, cameras, or spectrometers) and its targeted ejection if it fails to meet conformity criteria.

In these very high-throughput processes—sometimes several hundred ejections per second—performance does not depend solely on detection quality. It largely hinges on the speed, repeatability, and power of the air jet produced by the solenoid valve.

This is where MAC Valves technology makes the difference.

Thanks to their exceptional response time, extended service life, and ability to maintain consistent performance in harsh environments, MAC solenoid valves deliver more precise, faster, and more reliable sorting.

Learn more about optical sorting

The Three Main Families of Optical Sorting

MAC Valves are used across several types of optical sorting, each suited to a given product type or production line: air-jet sorting, pusher/paddle sorting, and free-fall sorting.

Air-Jet Sorting

Products are conveyed flat on a belt, pass in front of an optical sensor, then are sorted using an air jet expelled through a nozzle controlled by a solenoid valve.

Typical applications :

Recycling (plastics, paper, bottles)

Food industry (flat, dry products)

Sorting of industrial parts.

Technical specifics :

Blow from below, above, or both sides

Valves synchronized by detection

In-line valve bars

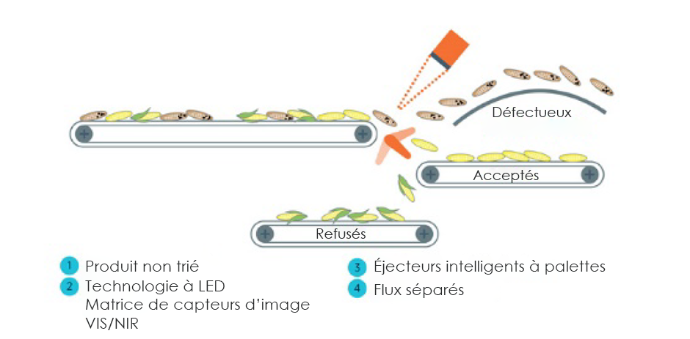

Pusher or Paddle Sorting

A product detected as non-compliant is physically pushed off the line using a pneumatic cylinder (controlled by a solenoid valve) or a rotary system.

Typical applications :

Food industry (fruits and vegetables, potatoes, tomatoes, citrus, etc.).

Particular features:

Suitable for unstable or rolling products

Controlled ejection force

Reduced risk of product damage

Technical specifics :

Requires a fast, consistent solenoid valve (dedicated MAC Valves ranges).

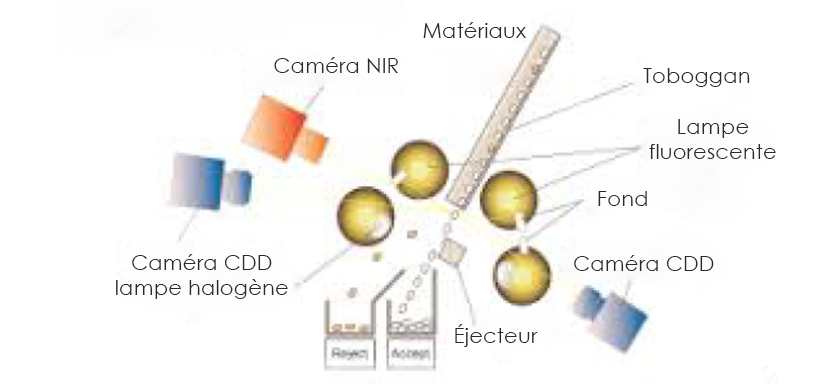

Free-Fall Sorting

Products fall in free fall in front of a camera. When a product must be ejected, a vertical air jet is triggered via a nozzle controlled by a solenoid valve.

Typical applications :

Food industry (rice, grains, coffee, lentils, pellets, seeds, etc.).

Particular features:

No conveyor required

Very high precision in flow

Suited to high speeds for small, light, fast-moving products.

Technical specifics :

64 to 320 channels in parallel

Direct control from the optical controller

Compact, high-frequency solenoid valves.

Free-Fall Sorting

Products fall in free fall in front of a camera. When a product must be ejected, a vertical air jet is triggered via a nozzle controlled by a solenoid valve.

Typical applications :

Food industry (rice, grains, coffee, lentils, pellets, seeds, etc.).

Particular features:

No conveyor required

Very high precision in flow

Suited to high speeds for small, light, fast-moving products.

Technical specifics :

64 to 320 channels in parallel

Direct control from the optical controller

Compact, high-frequency solenoid valves.

How Do Solenoid Valves Work?

In an optical sorting system, the quality of the air jet depends not only on the valve’s mechanics. The electrical drive signal is just as critical. It affects:

- Valve opening speed

- Cycle repeatability

- Heat generated in the coil

- Signal stability at high frequency

1

Square-wave signal (24 VDC)

The solenoid valve receives a square electrical signal at 24 VDC. The maximum on-time (coil energization time) may be limited depending on coil power.

Simple to use

No cable-length limitations

2

On-time + reduced holding voltage/current

The valve is driven by a square signal (e.g., 24 VDC) for a defined time to open. A lower holding voltage is then applied (e.g., 10 VDC) to keep it open, reducing energy while maintaining the active state.

No cable-length limitations

Faster de-energize time

Optimized power consumption

Less coil heating

3

On-time drive with PWM holding

(Pulse Width Modulation)

The valve receives a square signal (e.g., 24 VDC) for a defined time to open. A PWM signal is then applied to hold the valve, modulating delivered power to keep the state with reduced energy.

Single power supply required

Reduced de-energize time

Lower energy use

Less coil heating

4

PWM control via three-wire circuit

The PWM signal can also be delivered via a three-wire connection between the PLC and the valve. In this setup, the circuit handles power/current directly, while the PLC provides only the command signal (not the load power).

PLC does not source the current

PLC outputs only the trigger

Faster de-energize time

Reduced de-energize time

Less coil heating

Optional use of PWM technology

MAC Valves uses PWM as an option to save energy and/or protect the coil during long holding phases.

PWM can be integrated into your control electronics, into the control lead, or directly on the valve coil.

Easy installation

No overheating

Exceptional repeatability

High-frequency compatible

Impact of the signal on performance:

- Energize time

- De-energize time

- Pressure rise time at the nozzle

- Consistency of the air jet

A poorly defined drive signal can cause:

- Less accurate sorting

- Excess energy consumption

- Premature valve wear

Net Impact Force” (NIF): measuring the actual ejection force of your system

In high-throughput optical sorting, the air-jet power determines whether the targeted object is correctly ejected. But this power isn’t just a theoretical pressure or flow value: it is measured at the nozzle, at the exact moment the solenoid valve is activated. This is what MAC Valves calls Net Impact Force (NIF).

NIF is a standardized measurement of the impact force of the air burst at the nozzle outlet, expressed in grams or newtons. It accounts for:

- Solenoid valve response times (opening/closing)

- Air volume delivered over a very short duration

- The shape of the generated pressure waveform

- Mechanical design of the channel between valve and nozzle

It is measured using a dynamic piezo force sensor, an oscilloscope, or a standardized nozzle.

(Illustration: TLD OI Technologies, Net Impact Force type)

Phases of the air-jet impact

Mechanical response time (T0)

Time between the start of the electrical signal and the start of mechanical opening of the solenoid valve.

Pressure build-up (T1)

Filling of the circuit until the blow-off threshold is reached.

Actual impact (T2)

(T2)

Onset of the mechanical ejection force acting on the target object.

Actual impact (T2)

(T2)

Onset of the mechanical ejection force acting on the target object.

De-energize (T3)

Time between cutting the electrical signal and the start of mechanical closing of the solenoid valve.

De-energize (T3)

Time between cutting the electrical signal and the start of mechanical closing of the solenoid valve.

End of ejection impact (T4)

End of the ejection force acting on the object.

End of ejection impact (T4)

End of the ejection force acting on the object.

Drain

(T5)

End of purging of the ejection circuit.

Drain

(T5)

End of purging of the ejection circuit.

Optimizing Optical Sorting via Pneumatic Circuit Design

The channel connecting the valve outlet to the nozzle should be as short as possible, with a constant diameter and no turbulence. This ensures laminar flow, minimal pressure loss, and a more consistent jet.

Nozzle design influences jet shape, concentration, reach, and response to pressure.

Valve type selection: axial or radial flow

MAC Valves for Optical Sorting

The patented Bullet Valve®, featuring MAC’s latest technology, uses a specific design that guarantees extremely precise response times and flow rates. The Bullet Valve® flow is factory-set during assembly to your application by simply adjusting the poppet stroke.

Adjusting the stroke between the permanent magnet and the poppet in the coil also improves valve-to-valve repeatability of response times.

These two essential MAC characteristics are checked on every valve at end-of-line (not by sampling), enabling production of valves with identical response times and flow rates.

1- Bullet Valves® — Series BV210, BV214, BV221

General features

Multiple seal and body materials

Fast response times

Excellent cycle-to-cycle repeatability

Low-friction design

High actuation forces

Benefits

Compatible with numerous gases and fluids

Excellent sealing

Fewer wear points than traditional technologies

Long service life

Virtually zero dead volume

2- Bullet Valves® with Double Diaphragm — Series BV210DD to BV221DD

General features

Very short response times thanks to reduced friction

High repeatability.

Pressure-balanced design

Factory-set flow adjustment available

MAC Valves technology

Benefits

Ideal for variable-pressure applications

Very precise dosing

Quiet operation

Customizable

High flow in a compact footprint

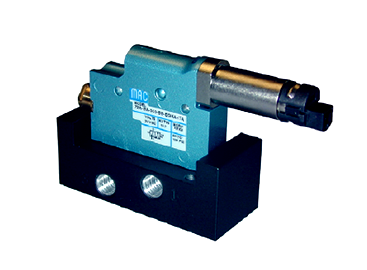

3- Pneumatic Solenoid Valves for Air-Jet Sorting — Series 34, 52, 72

Series 34 — 3/2

- High flow in a small footprint

- Fast response times

- Very long life (estimated: 1 billion cycles)

- Large-diameter body bore

- Conical seat

- RPTE to ensure consistent response times (RPTE = MAC proprietary technology)

- 10 mm, direct-acting valve

- Balanced poppet, insensitive to pressure variations

- Patented coil generating high shifting forces

- Powerful return spring

Series 72 — 3/2

- Balanced poppet

- Patented conical seats for extended life

- High flow

- Overmolded low-friction poppet

- Wiping effect prevents sticking

- Extremely high repeatability

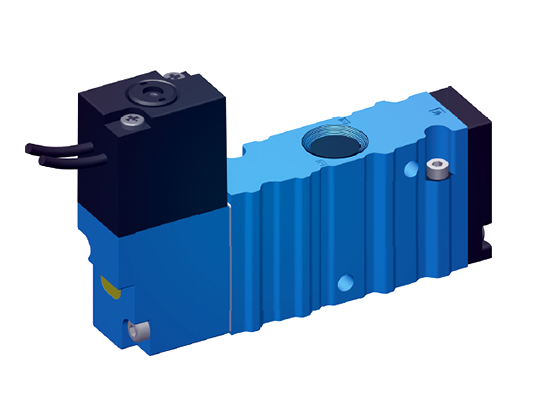

Series 52 — 4/2

- Four-way pilots generating maximum shifting force in both directions

- Pressure-balanced spool, insensitive to pressure variations, ensuring high flow

- Short stroke with high flow

- Overmolded low-friction spool sliding in a mirror-finish bore

- RPTE technology for consistent response times

- Wiping effect eliminates sticking risk

- Long service life

- High-speed response

- High flow in a compact design

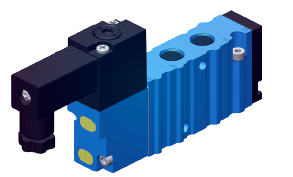

4- Pneumatic Solenoid Valves for Paddle Ejection — Series 400

Series 400 — 5/2

- 5/2 pilot generating maximum shifting force in both directions

- Memory spring available

- Pressure-balanced spool, insensitive to pressure variations, delivering high flow

- Short stroke with high flow

- Overmolded low-friction spool sliding in a mirror-finish bore

- Wiping effect prevents sticking

- Long service life

Our components

Peri robotic

Mecatronic

All fluid